CURIOSITY

Robot in 30 Hours

What is this event?

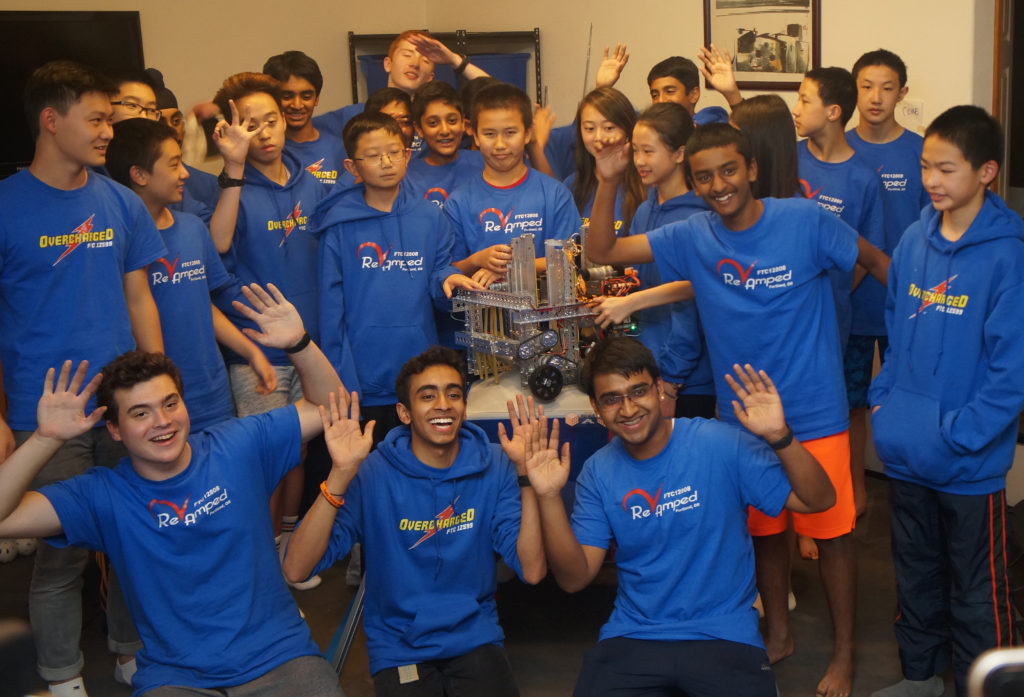

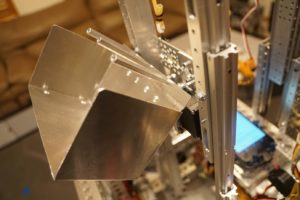

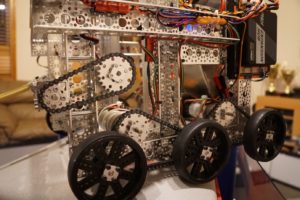

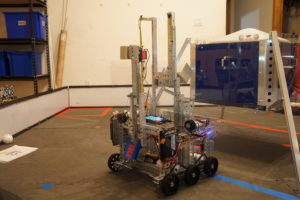

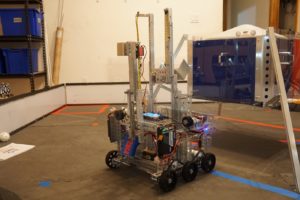

The Robot In 30 Hours Event, hosted by RevAmped Robotics and Overcharged, is an event that aims to help the broad FTC community by showing the procedure of designing, building, and programming a robot for the upcoming FTC Rover Ruckus game. In this event, we are going to analyze the game that has just come out, create a basic design, build a robot to complete certain tasks, and possibly program a basic autonomous – all in 30 Hours! During this event, we will be providing regular updates every 2 hours on this YouTube channel, where we will be discussing what we have designed, going over any prototypes that are in progress, and hopefully demonstrating a robot that is successful at certain elements of the challenge! We will also be posting regular updates to our Facebook and Instagram, so check us out!

Why are we doing this?

Simply put, designing can be extremely hard for all teams, regardless of experience level or capabilities. One of the cornerstones of FTC is to see how other teams tackle a challenge, and build upon that idea to be successful. We wanted to help jump start that process for as many teams as possible by creating a fully functional robot by the end of the first weekend. In addition to this, we wanted to use this opportunity to familiarize our team with the build principles of basic stock components. By familiarizing our team with the Actobotics build system, we will be better prepared for the design and fabrication components of the Rover Ruckus season. Because one of our main goals with this activity was to help spread what we learned with the FTC community, we created a video playlist showcasing our progress and giving a detailed rundown of our robot. You can check that out below!

Our Goals

Inspire Other Teams

Share our Knowledge

Challenge Ourselves

Understand Rover Ruckus

How did we prepare?

Our team has done a lot over the summer to allow our new members to understand the fundamentals of the design and build process for the season. In the summer, our members split into two groups, with one of them working to improve our 2017-18 Relic Recovery robot, and the other working on building a completely redesigned, 6-wheel drivetrain for the upcoming Rover Ruckus season. In late July, a few of our veteran members attended an extensive advanced fabrication course at the Portland Community College, where they learned how to use the Vertical Mill, Lathe, and CNC. These members brought back their newfound experience and trained members from both RevAmped and Overcharged in a two-week, extensive training course, the curriculum of which they created themselves. Finally, a week before this challenge, all of our members worked on building basic designs with Actobotics to become familiar with the Actobotics build system, as that is the system that we used for our Ri30H challenge.

What we Learned From This

How to Plan Robot Design

How to use Advanced Fabrication Machinery

How to Implement Changes on a Completed Robot

What did we learn from Ri30H?

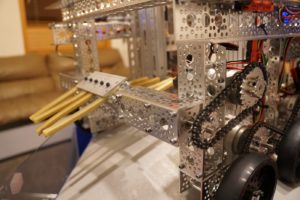

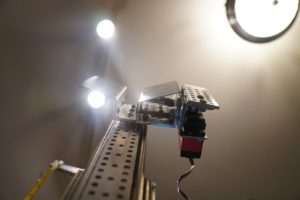

The challenge was a resounding success! We were able to design, build and program a robot that could complete every task for Rover Ruckus in under 30 hours! We learned a lot in every step of the way, from brainstorming to putting together a final product. First, we found that the most effective brainstorming method for such a large team (26 students!) is to split the group into smaller 5-6 student subteams, where all students have the chance to promote their ideas. After this, each subteam should attempt to combine some of the ideas to create a more effective machine. Finally, after creating this hybrid, each subteam will present their ideas to the entire team, where students will then find ways to combine these ideas to create the most effective machine possible. After brainstorming came prototyping, and we found a distinct style of prototyping that worked better than all else. Having a test bed onto which the team could place various prototypes was found to be, by far, the most effective way to get proof of concepts onto the field, interacting with the various game elements. Finally, we found that it is extremely beneficial to have a person in charge of integration while designs come together. Especially in such a time crunch, many separate designs need work done to fit smoothly on the robot, and having a specific team dedicated to this drastically reduces the chances of error when putting together the final product.

What we Learned From This

Our Strategy

It's Outcome

Crystal clear goal setting

Everyone in the team knew what we were doing

Splitting into smaller groups

Sub-teams dedicated to each task

More active involvement from team members

Each team had a more focused approach to their tasks

Testing on a test-bed

Testing each prototype before implementing on the bot

Individual component testing, interactive testing and integrated testing

Allowed for a proof of concept before committing

Worked out kinks before placing on bot

Allowed the integration process of the final robot to happen effectively and smoothly

Progressive Video Updates

Provided detailed documentation of our process – helped keep our viewers in the loop as we progressed!